Cryogenics

As dry as He can get

2 Jun 2020

Before it gets processed in the cold boxes of the ITER cryoplant, gaseous helium need to be perfectly dry—and this means removing every single water molecule that it might contain.

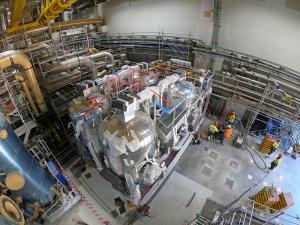

Cold boxes do not like water. Before it is processed, gaseous helium needs to be perfectly dry to prevent damage. This crucial operation is the task of a 56-tonne "helium dryer" that was installed in the cryoplant on 27 May.

This operation is tasked to the massive "helium dryer" that was installed on 27 May in ITER's "cold factory." Manufactured by Air Liquide under a contract from the European Domestic Agency Fusion for Energy, the 56-tonne component is one of the very last elements to be installed in the ITER cryoplant.

Click here to view a video of helium dryer installation.