Long-term coil park

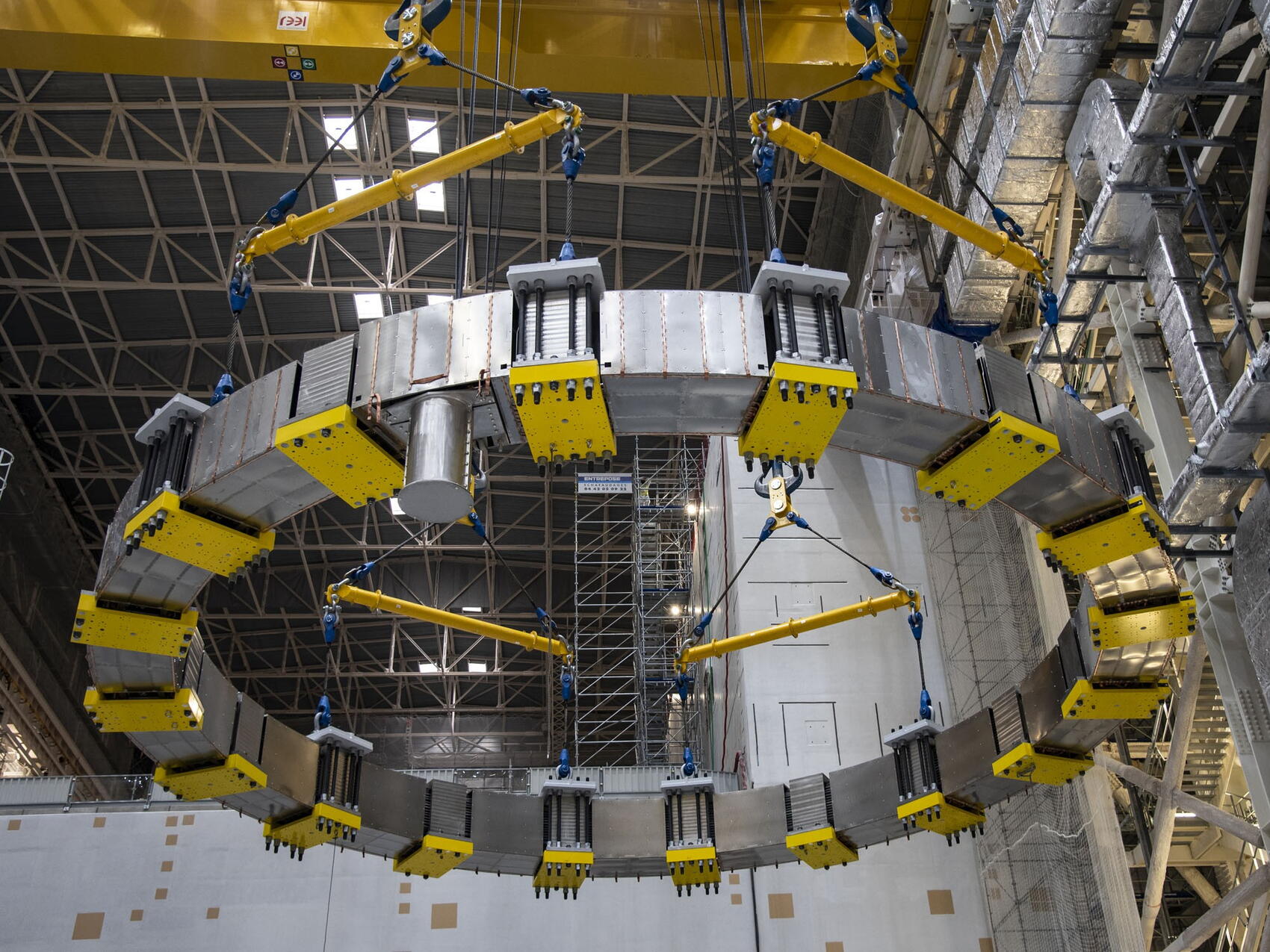

Manufactured in China under a European contract, poloidal field coil #6 (PF6) was the first magnet to be installed in the assembly pit in late April 2021. Sailing the south China Sea, the Indian Ocean, the Red Sea and the Suez Canal into the Mediterranean, it travelled more than 10,000 kilometres to reach the ITER construction site. For its successor in the assembly sequence, poloidal field coil #5 (PF5), the trip was much shorter: just a few hundred metres from the European poloidal field coil winding facility on site to the Assembly Hall and into the assembly pit. With the installation of this second ring-shaped coil on 16 September, ITER has achieved yet another major assembly milestone.

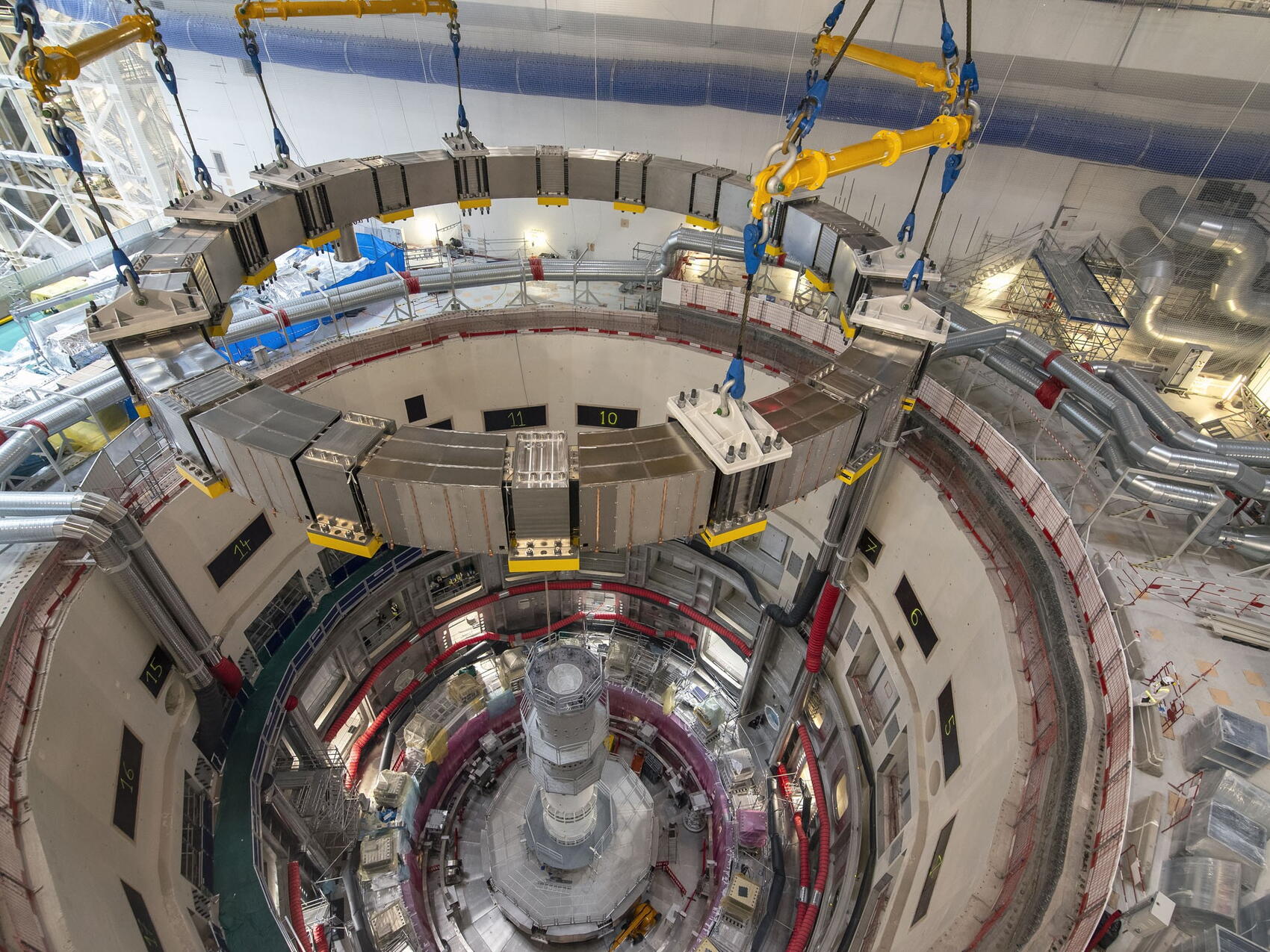

On Monday 26 July, the coil was moved out of temporary storage and into the Assembly Hall. A few weeks of preparation and rigging followed, and by 15 September it was ready for installation.

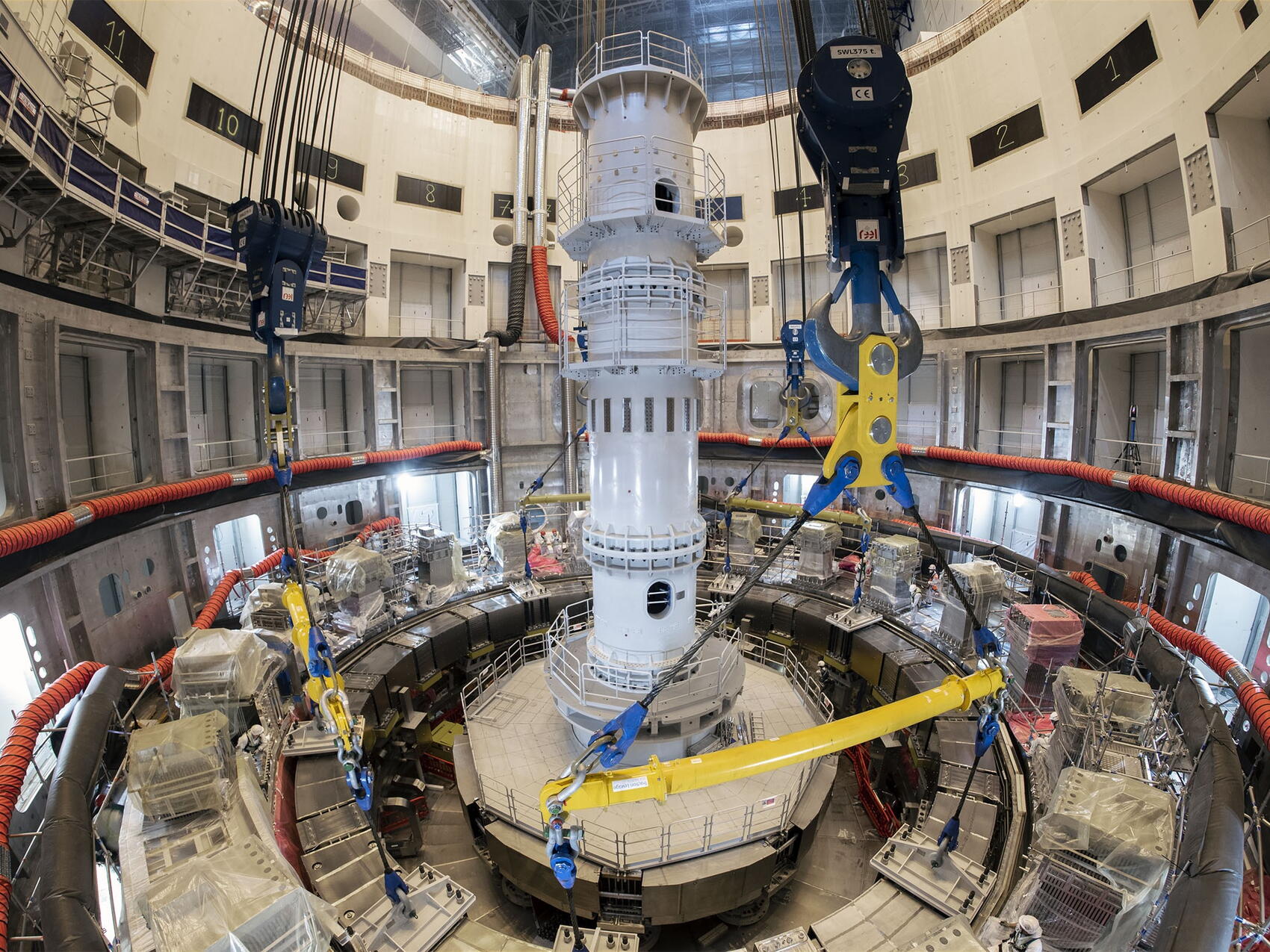

Once lowered into the pit, the coil had to fit precisely on its supports, just above magnet feeder components and a few centimetres from the surface of the lower cryostat thermal shield. Early in the afternoon of 16 September, PF5 was its final "parking position," with all position requirements within tolerance.

Like its neighbour PF6, PF5 will remain in a temporary position for a few years. When all vacuum vessel sectors are in place, both coils will be raised to their permanent position (a move of approximately 2 metres for PF6 and 1.5 metres for PF5).

Click here to view a video of PF5 installation.