First ITER magnet arrives this year

A major milepost is projected for 2019 as the first of ITER's powerful, high-field magnets is scheduled to arrive from Japan. Let's take a look behind the scenes at the last-stage fabrication activities that are mobilizing the expertise and skill of heavy industry specialists under the responsibility of Japanese QST, the National Institutes for Quantum and Radiological Science and Technology.

Eleven years after completing the signatures on documents specifying technical and quality control requirements for the supply of nine toroidal field coils, the Japanese Domestic Agency is overseeing the last, spectacular sequences on its first production unit.

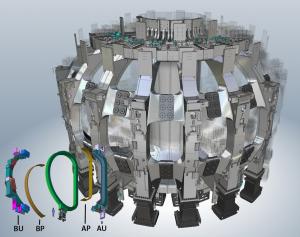

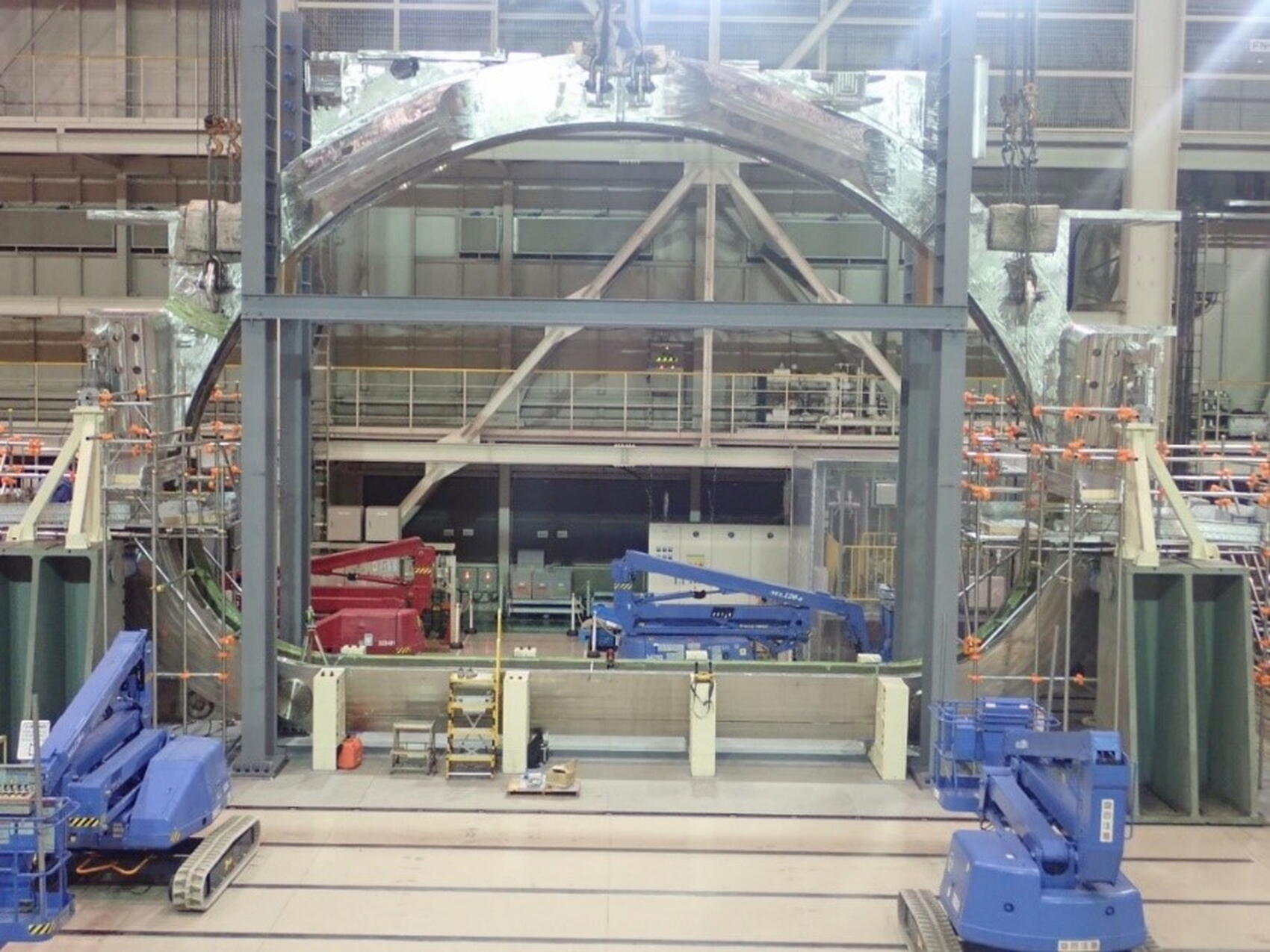

The first winding pack to come off the assembly line in Japan is currently undergoing final inspection by the industrial consortium Mitsubishi Heavy Industries/Mitsubishi Electric Corporation. The final sequence of testing involved high voltage tests, helium leak tests, and finally cryogenic tests, during which the winding pack is inserted into a cryostat (see top photo) and cooled to 80 K (-193 ˚C) to confirm leak tightness. With the successful end of cold testing, the winding pack is now undergoing post-cold-test helium leak tests and high voltage tests and will soon be ready for assembly with its toroidal field coil case. Five other winding packs are in various stages of production.

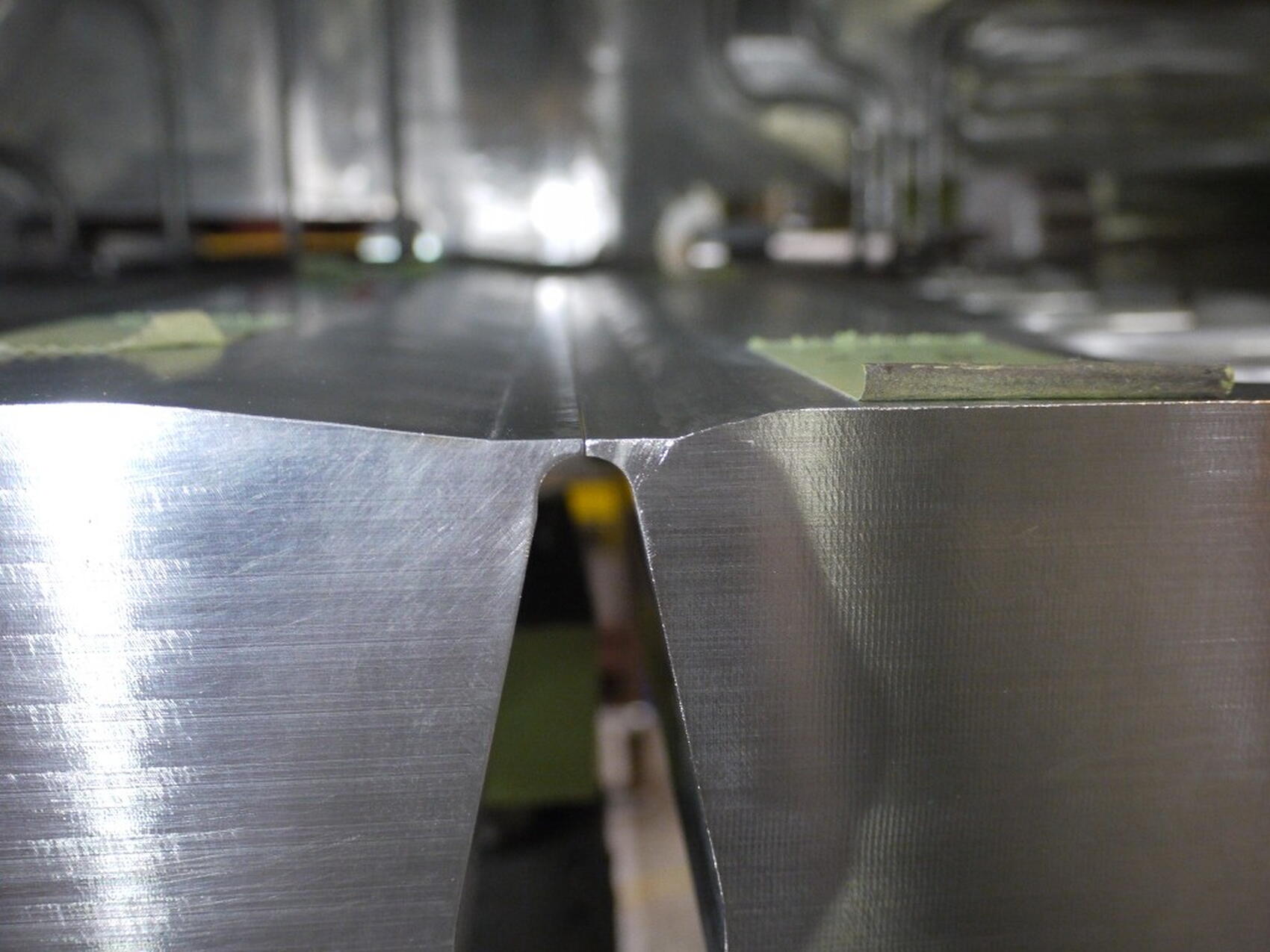

The 200-tonne case assemblies are also in series production. After successful fitting tests early last year, two have been delivered to Europe for insertion activities and a third will arrive this month; another completed production unit will remain at Mitsubishi for the assembly of the Japanese coil that is due at ITER in 2019. The fitting tests are the most delicate stage in the coil case manufacturing process, demonstrating that sub-assemblies manufactured and welded at different factory sites can be successfully paired with gap tolerances as strict as 0.25 to 0.75 mm along 15-metre weld grooves.

Please see the gallery below for a full update on manufacturing progress.