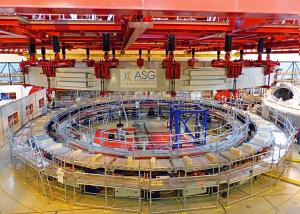

From the start of coil winding activities in

September 2017, to the resin impregnation of the fully formed coil last month, the realization of poloidal field coil #5 (PF5) has been a meticulous, stage-by-stage process. It is now just one step from completion, as the coil has been moved to the final workstation for cleaning, testing (dimensional and electrical), covering and clamping.

Nearly 12 kilometres of niobium-titanium (NbTi) conductor have gone into the winding of PF5, which is formed from eight individually impregnated double pancakes. The pancakes were

stacked, joined electrically, and wrapped in ground insulation (glass/kapton tape) in preparation for vacuum pressure impregnation—a process that confers rigidity to the final winding pack and insulates the coil electrically.