Un « renfort solide » pour un composant fragile

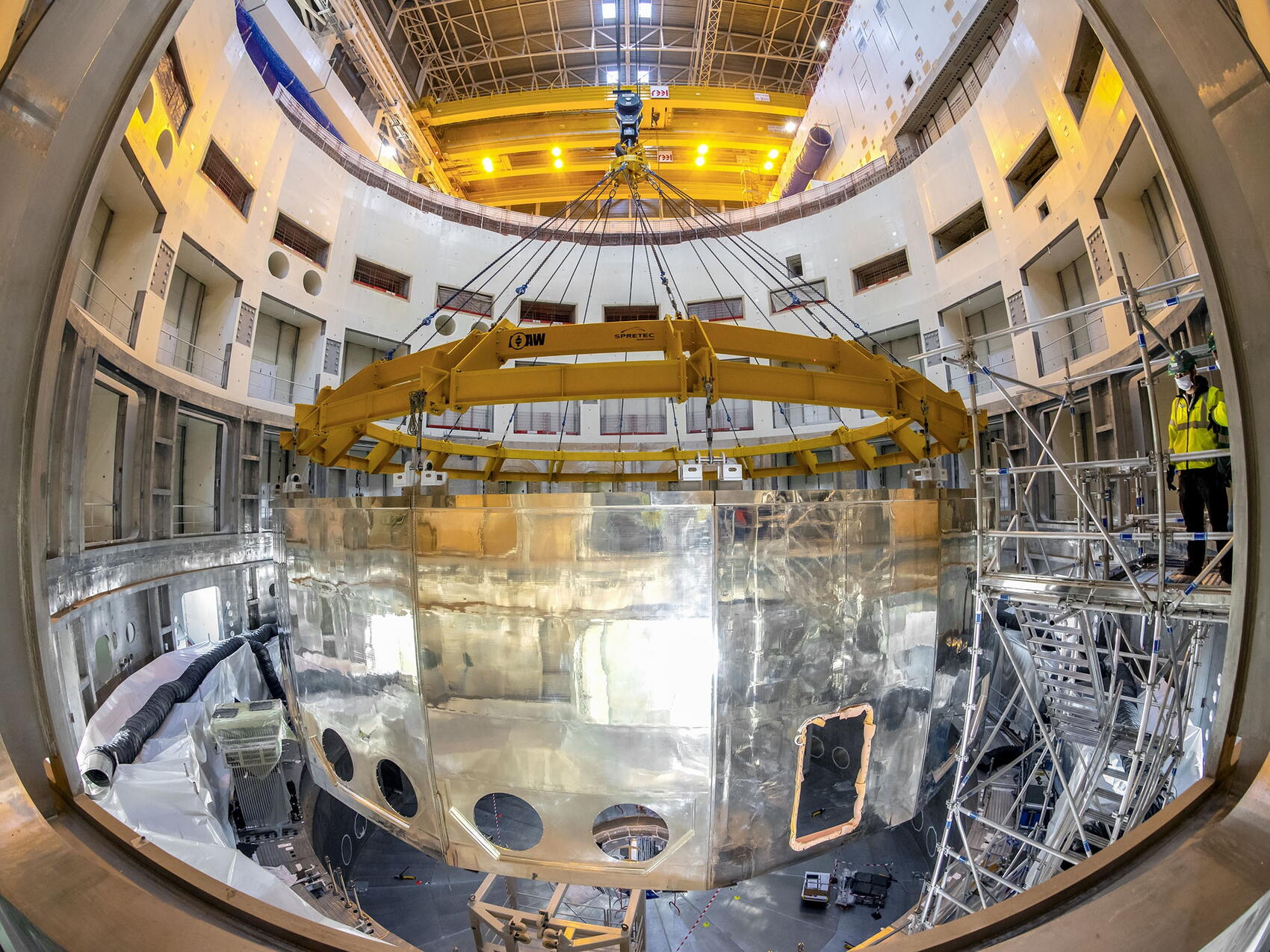

Après l'installation de la base et du cylindre inférieur du cryostat, respectivement en mai et en août de l'année passée, l'opération du jeudi 14 janvier a été un autre instant mémorable de l'assemblage de la machine ITER. L'aspect du composant, dont la surface argentée reflétait les couleurs et les formes de son environnement, son apparente fragilité ainsi que sa manipulation délicate ont tous contribué à la grâce de l'événement.

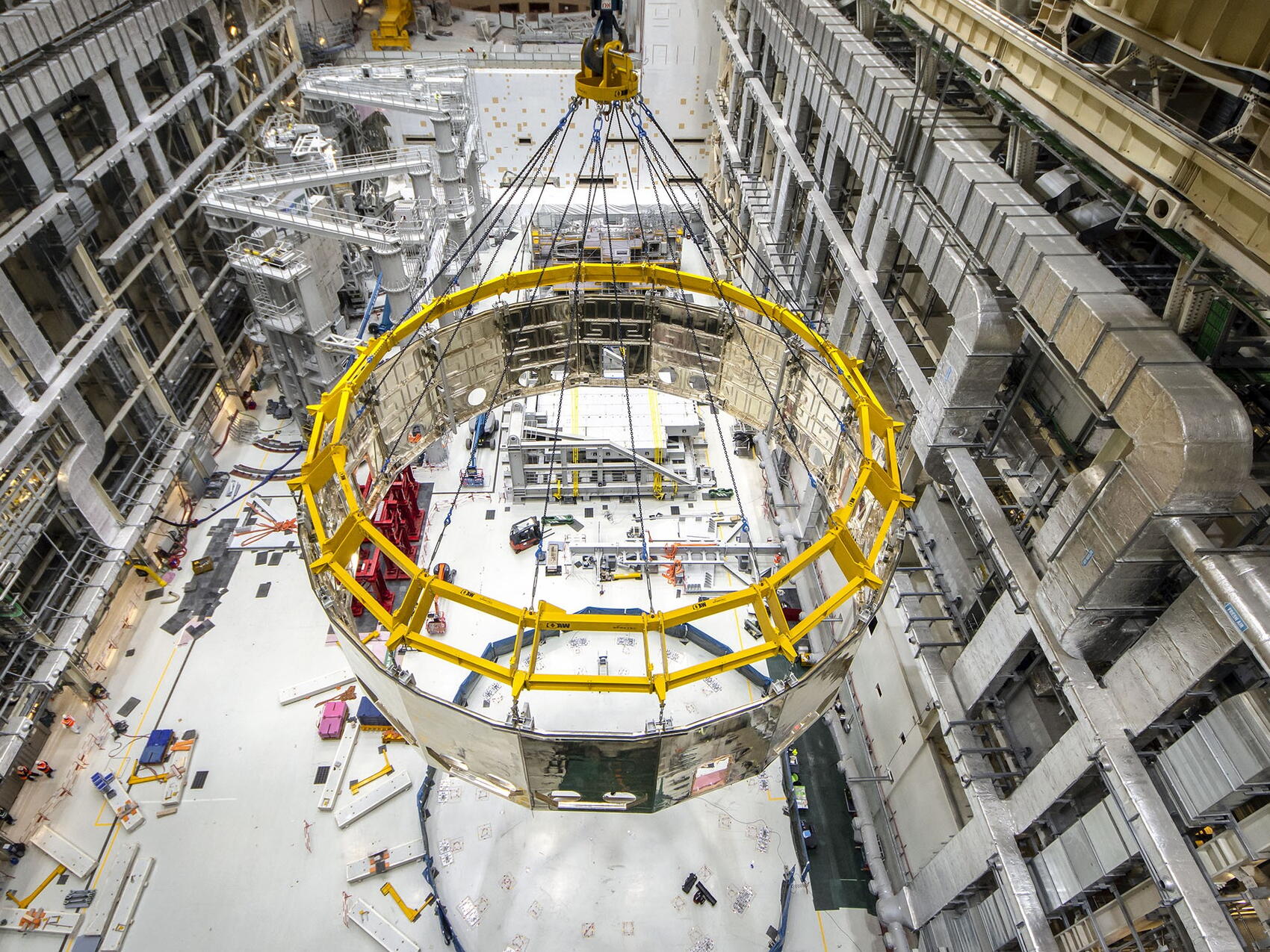

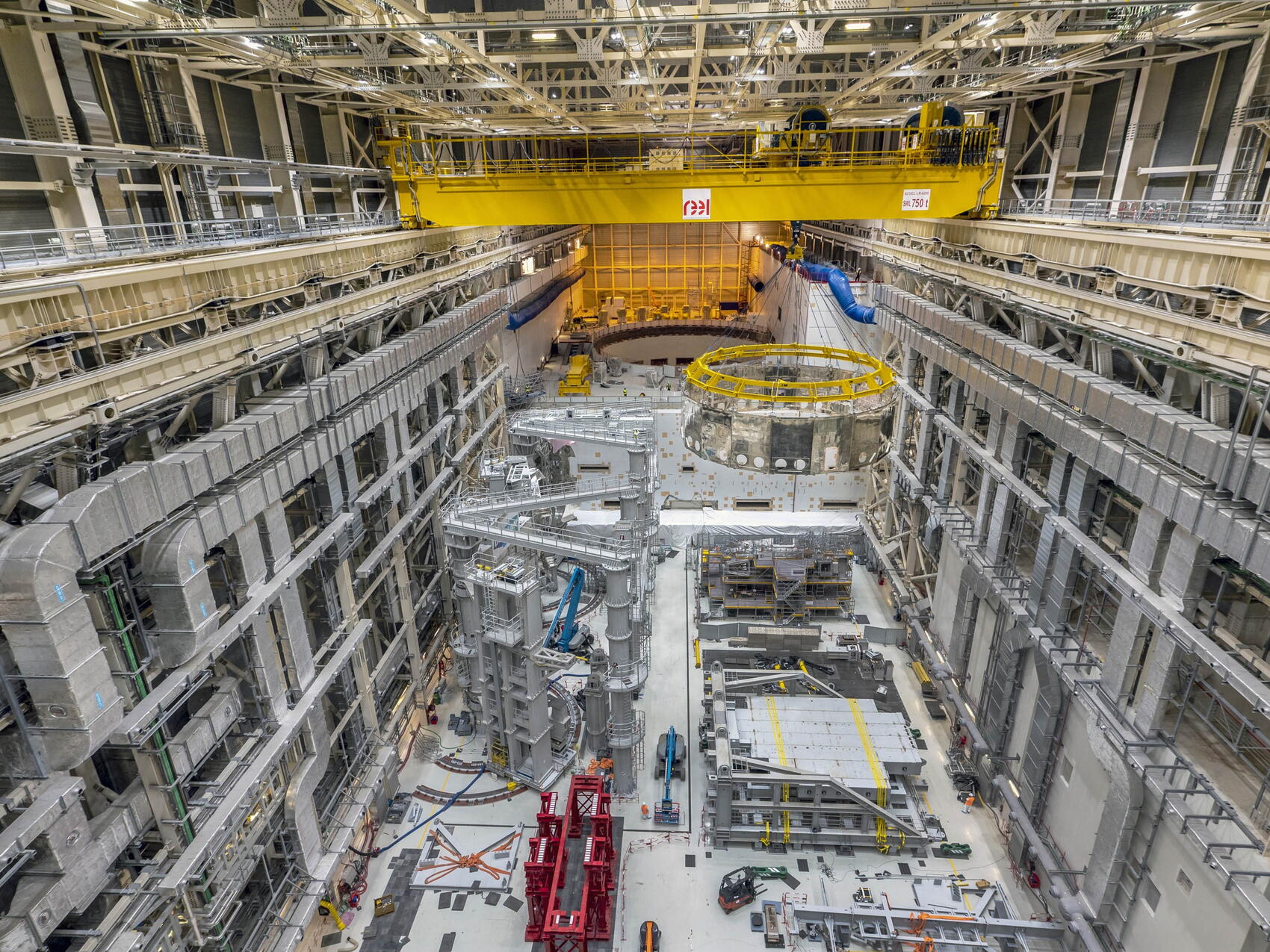

Suivant une séquence devenue familière, la charge a d'abord été soulevée de quelques centimètres, le temps de vérifier son équilibre et d'effectuer des mesures, puis élevée jusqu'à sa hauteur de croisière d'environ 23 mètres au-dessus du plancher du Hall d'assemblage. Une fois le composant aligné sur l'axe du puits d'assemblage, l'aventure a commencé : un parcours d'une centaine de mètres à la vitesse relativement rapide de 2 mètres par minute, ponctué par le passage délicat au-dessus des grands outils d'assemblage parsemant le chemin et du mur séparant le Hall d'assemblage proprement dit de l'ouverture du puits du tokamak.

Comme souvent au cours des dernières étapes de l'installation de grands composants, l'approche finale requiert de tirer délicatement sur les câbles jusqu'à ce que l'alignement soit parfait. Jeudi dernier, cette technique de routine a été rendue plus difficile par la présence d'un support de bobine toroïdale récemment installé, dont les boulons d'ancrage saillants laissaient très peu de place pour manœuvrer.

De telles « difficultés inattendues », dues aux faibles écarts et aux interfaces complexes entre les composants, sont et resteront assez courantes durant la phase d'installation de la machine ITER. Jeudi, les opérateurs ont, comme toujours, géré la situation avec réactivité et ingéniosité.

Peu après 16 h 30, soit deux heures après avoir atteint le puits et cinq heures après le début du levage, le bouclier thermique du cryostat inférieur était en position voulue au fond du puits. Trois heures plus tard, la charge était transférée du pont roulant à un ensemble de vérins hydrauliques positionnés sur la base. Les réglages définitifs ont nécessité encore quelques heures et à 21 h 30, après une dernière série de mesures, l'opération était officiellement une réussite.