An ever-changing landscape

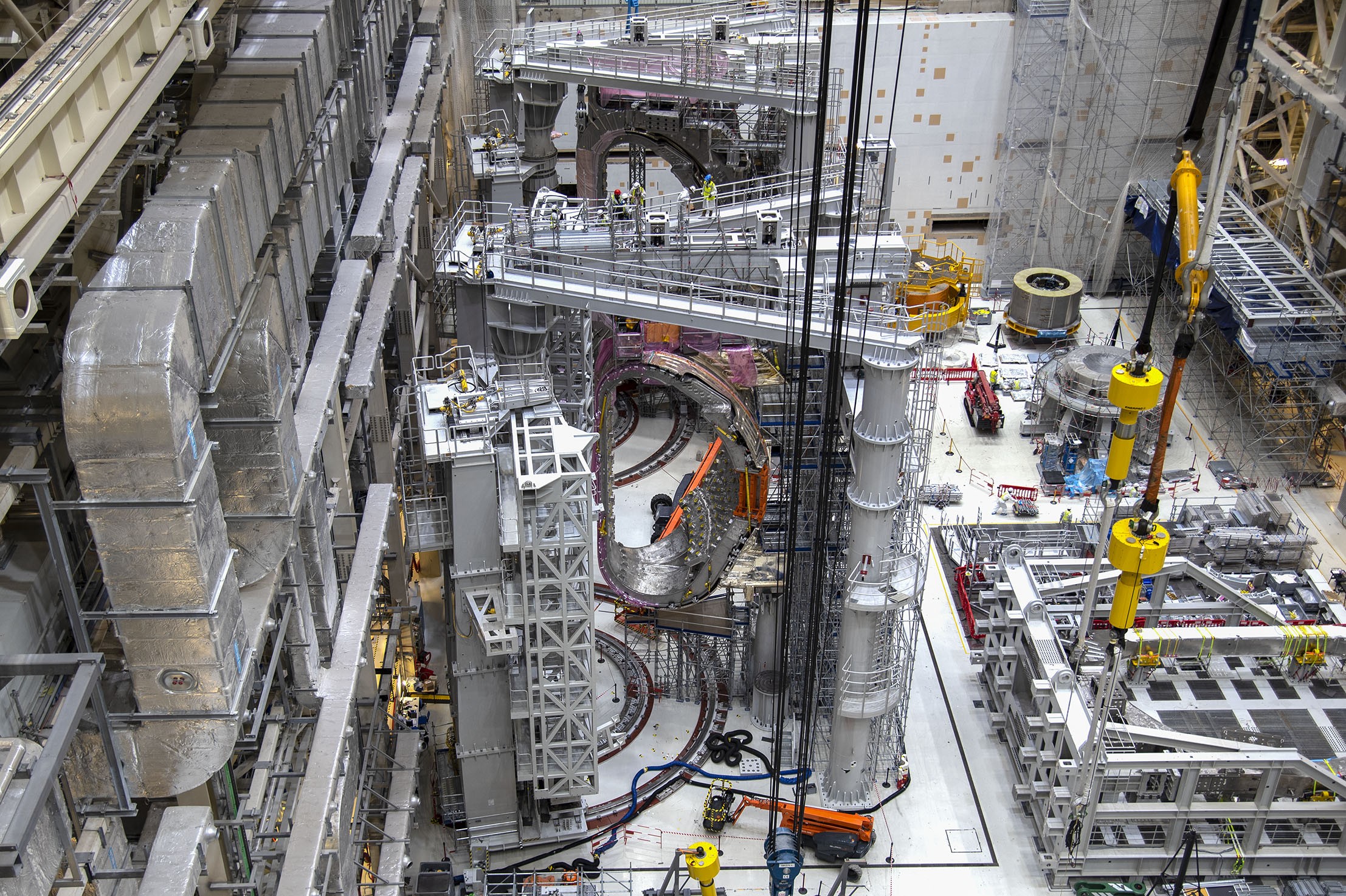

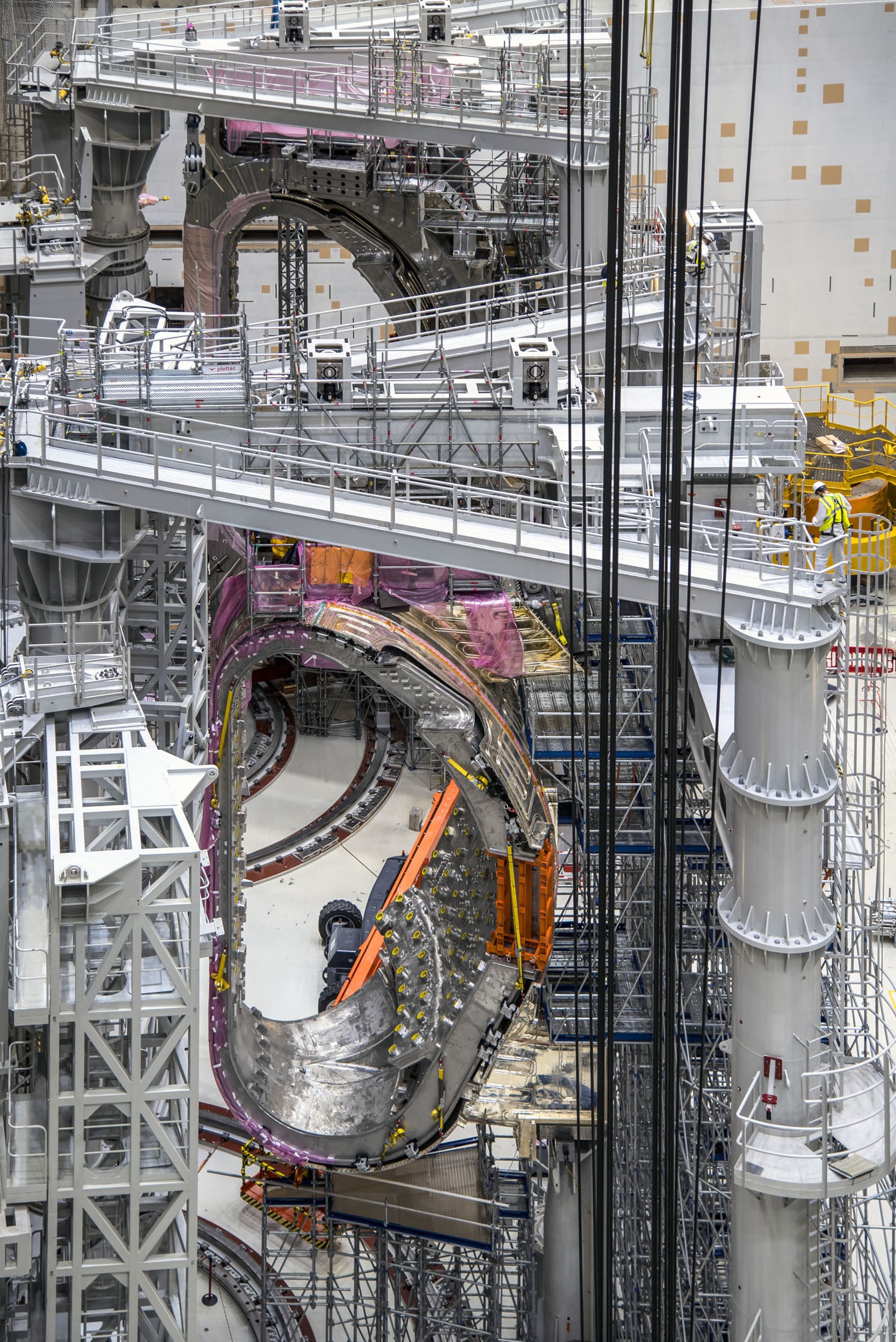

The view from the gangway, 55 metres above the floor of the Assembly Hall, is an ever-changing landscape. The 6,000-square-metre staging area accommodates only two permanent features: the twin sector sub-assembly tools (SSAT1 and SSAT2) designed to assemble the massive vacuum vessel sectors, toroidal field coils and thermal shield segments into sector modules. All around them, the movement of workers, elevated platforms, forklifts, rigging elements and giant components composes a slow-motion spectacle—half mechanical ballet, half construction game.

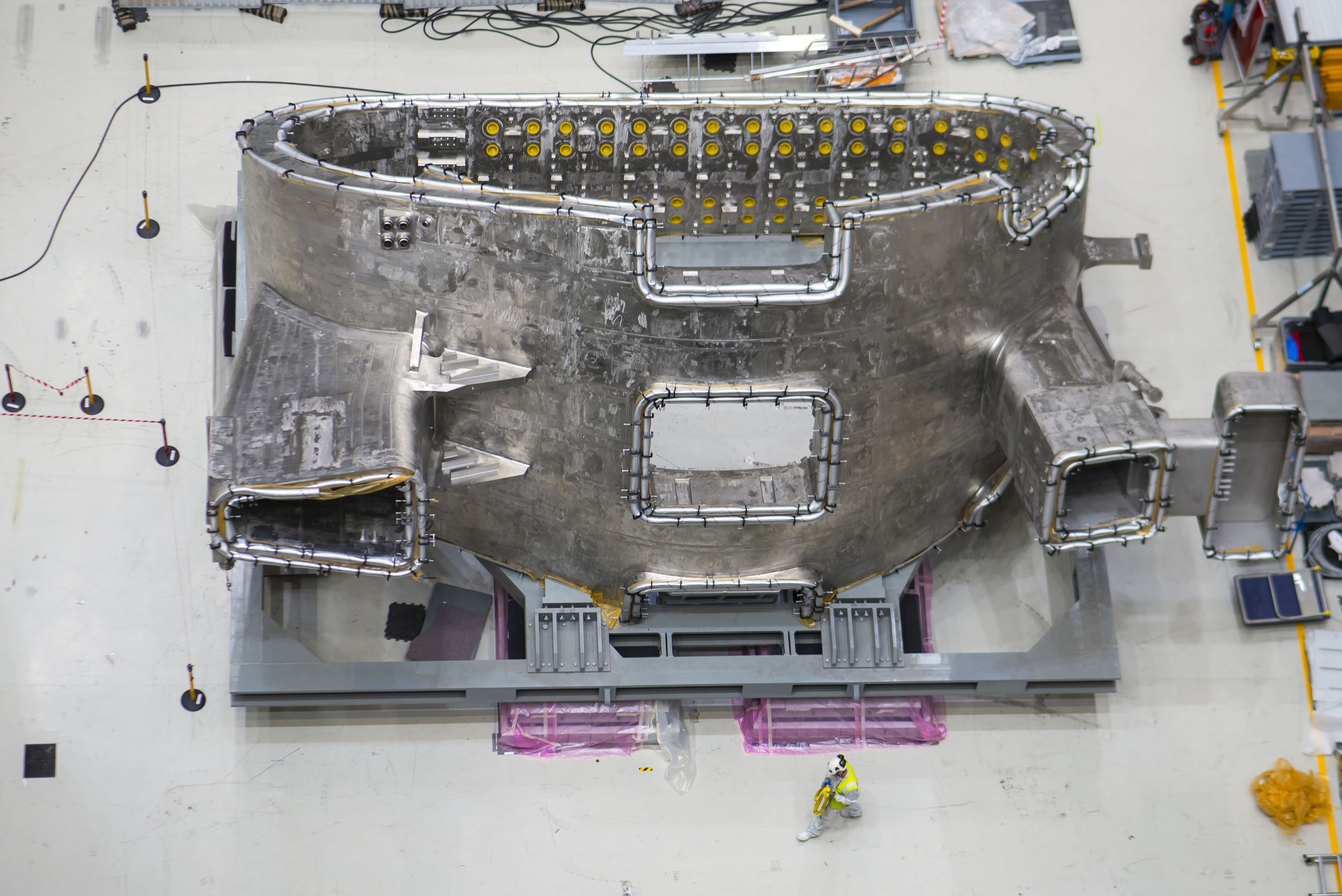

Close to the newly arrived sector, a toroidal field coil (#9 from Europe), lies in the upending tool (3). Soon, the tool will be moved to its vertical orientation and the magnet coil will be transferred to SSAT1 to be assembled with the second vacuum vessel sector, which has already been equipped with a thermal shield segment (4). A few metres away, SSAT2 holds a close-to-finalized sector module (5), scheduled to be installed in the assembly pit (6) in the coming weeks.

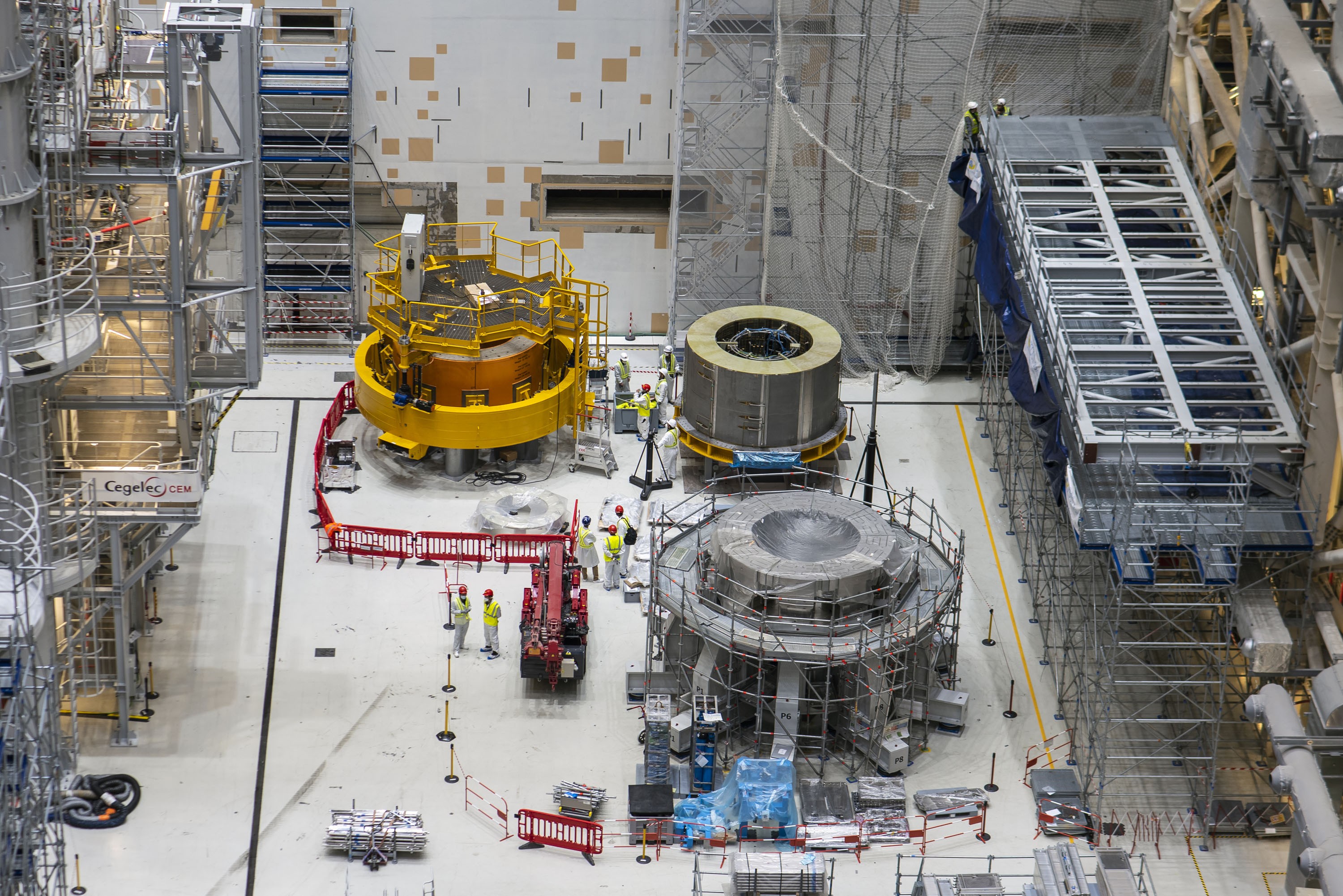

To the right of the twin assembly tools, an area (7) is dedicated to the assembly of the US-procured central solenoid modules. Of the three cylindrical elements, the greenish one is the first module, delivered to ITER in September 2021. The yellow tool to the left is the lifting fixture that will used to move the modules to the assembly platform (grey) and stack them one atop the other in order to form the 18-metre tall, 1,000-tonne central solenoid.

The structure along the wall, on the right side of the Hall (8) is part of the support system for the waveguides that will connect the gyrotron sources in the Radio Frequency Building to the tokamak machine.

As these lines are being written, the scene in the Assembly Hall has already been transformed, with the house-like cocoon for vacuum vessel sector #8 moved to temporary storage and readied for dismantlement.