Getting closer to the heat

For experts in divertor, and plasma boundary and wall physicsphysics, this meeting was of particular significance since important decisions about the strategy for the ITER divertor will be required within the coming two years. The question at stake is whether to start with tungsten (W) right away or whether to start with a carbon fibre-reinforced carbon composite (CFC) during the non-nuclear phase and switch to tungsten once the deuterium-tritium operations commence. (Also read Newsline # 196).

The ITPA DIVSOL research activities are therefore strongly focused on solving critical issues associated with issues such as the melting behavior of tungsten under uncontrolled events and the consequences this will have on plasma operation. Meanwhile, the CFC divertor remains the reference strategy before firm conclusions about the issues have been achieved.

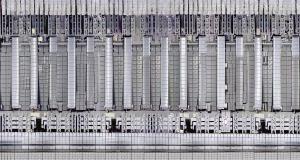

One of the highlights of this week's meeting was the discussion of first results coming from the recently installed "ITER-Like Wall" in the JET tokamak, jointly operated by the EU partners. JET is now running with the same material mix foreseen for the ITER plasma-facing components, using beryllium in the main chamber and a full tungsten divertor. First results show a significantly reduced retention of the plasma fuel in the wall materials, compared with equivalent operation with carbon walls. With a drastically reduced carbon plasma contact, low oxygen levels and low tungsten release rates at high density operations the overall performance of this material mix looks promising.