It's happening in the pit

There has always been something breathtaking about the vast cylindrical volume that will accommodate the ITER tokamak. When it was empty, it felt like a high-tech rendition of a Roman amphitheatre, complete with stands and terraces, and boxes for the happy few. As the 14,000-cubic-metre volume progressively fills with components and equipment, it now eludes comparison: nothing in the world remotely resembles what we call the "assembly pit."

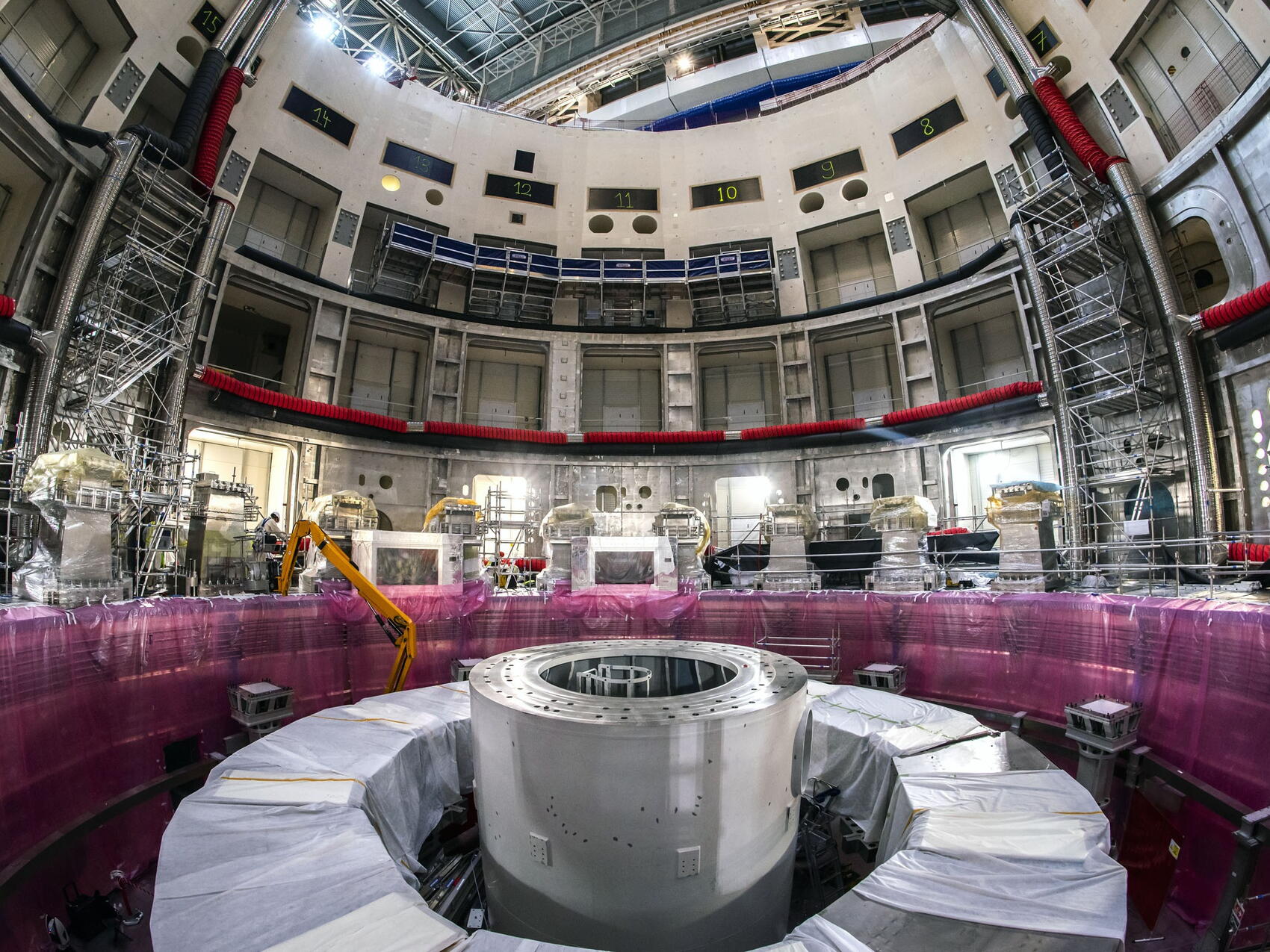

One year after the installation of the cryostat base, on 26 May 2020, there is nothing to remind us of the Roman amphitheatre. Stainless steel now lines the arena floor and lower half of the cylinder, the first-row seats are crowded with a circular arrangement of sturdy pedestal-like structures, and centre stage is almost fully occupied by components arranged in concentric circles.

For the occasional visitor, the feeling is one of strangeness, of a failure to grasp the function of all these elements and how they relate to one another. For the denizens of the ITER world, it all makes sense. What they see are the first steps of a prodigious undertaking: the assembly, from the bottom up, of the most complex machine ever designed.

First came the base section of the cryostat. The shape of a deep soup plate, it forms the bottom of the giant thermos that encloses the machine and provides thermal insulation to the superconducting magnets cooled to cryogenic temperature. With the subsequent installation of the 12-metre-tall lower cylinder, the cryostat now reaches halfway up the walls of the assembly pit. The thermos will be complete when the upper cylinder, presently in storage, and the top lid are installed at later stages of the assembly sequence.

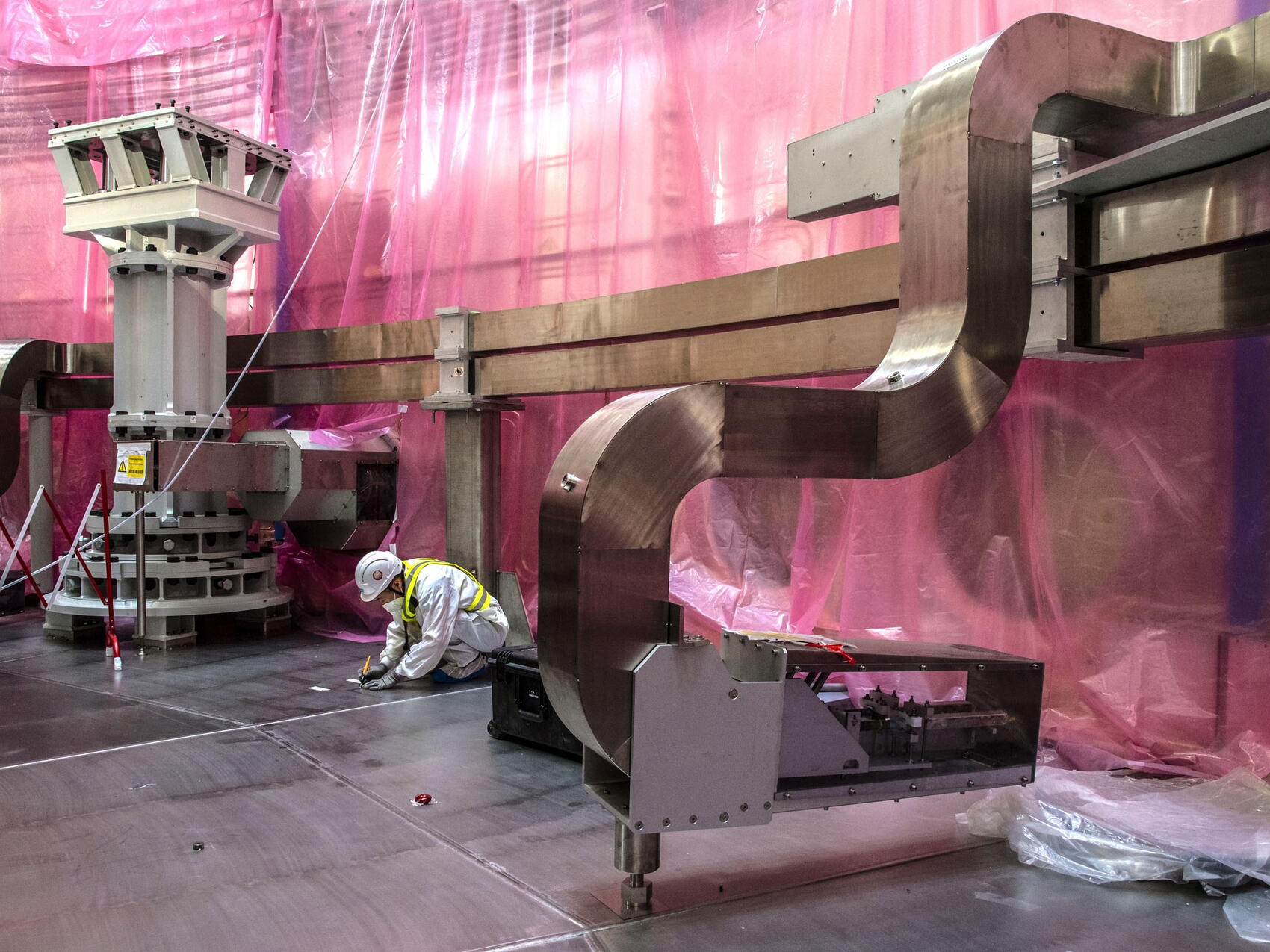

The vacuum inside the cryostat is not sufficient to protect the machine's magnetic system, which operates at the ultra-cold temperature of 4 K (minus 269 °C), from the warmth of the outside environment. An extra barrier, a "thermal shield," is needed to prevent heat transmission through the electromagnetic waves that any warm source generates, a physical phenomenon called "radiation."

The first section of the cryostat thermal shield was installed in mid-January 2021. The thin, actively cooled silver-plated component closely fits inside the depression in the cryostat base. Other sections will be installed as machine assembly progresses, eventually lining the entire interior surface of the cryostat wall.

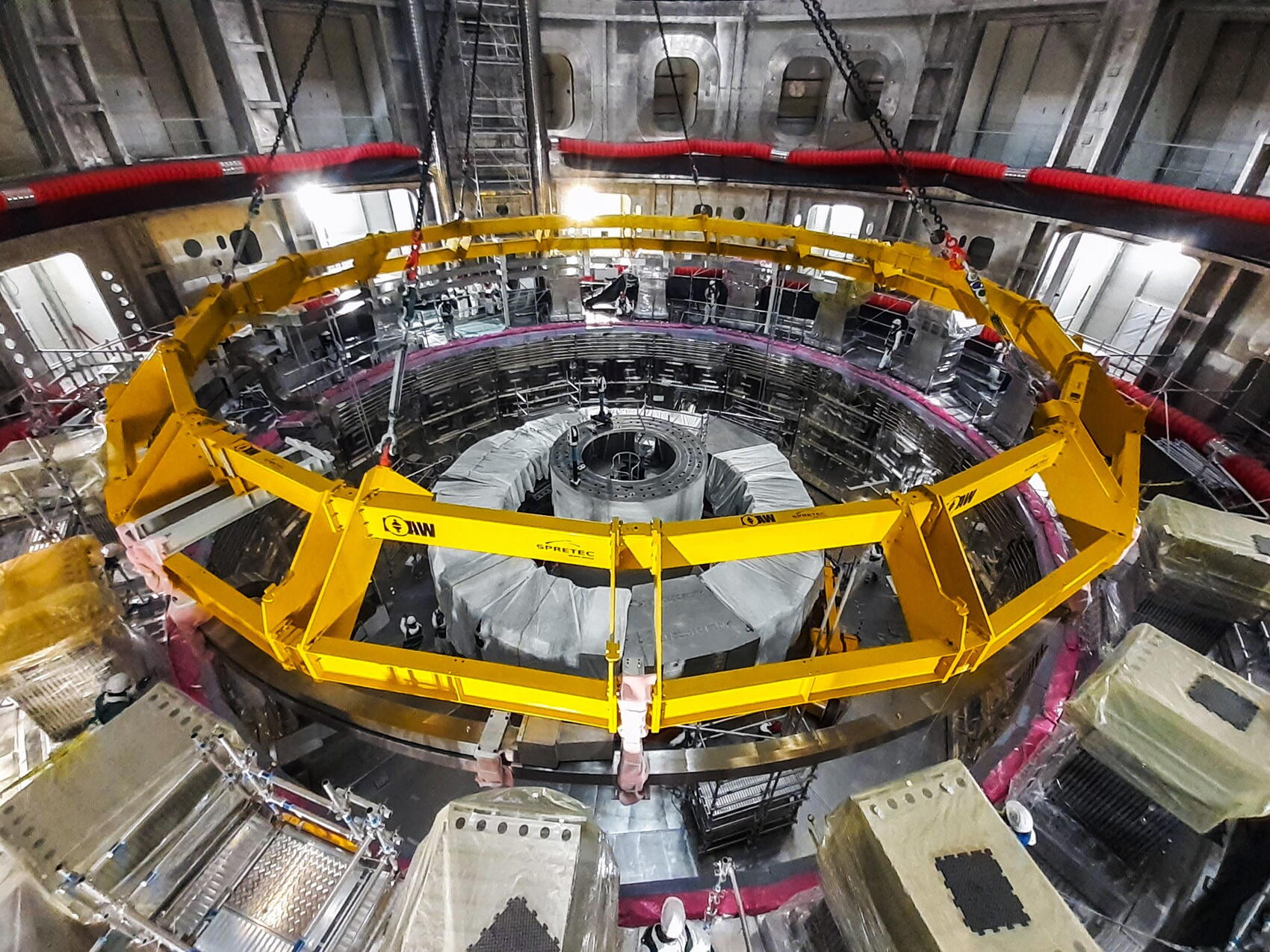

Early this year, smaller but no less strategic structures began appearing in the pit: the first of the 18 toroidal field gravity supports were bolted to the cryostat base rim, and temporary supports were installed to accommodate poloidal field coil #6 (PF6), the first ring magnet of the machine assembly sequence.

Along with machine components, the pit also accommodates temporary structures and tools that are required for the assembly process but that will be dismantled later. One of the most spectacular of these in-pit assembly tools is the central column, a 600-tonne tower-like structure that will stand more than 20 metres high and support the radial beams holding the nine sub-elements of the vacuum chamber as they are welded together. The first element of the central column was installed in March 2021; it now occupies the very centre of the pit.

The installation of PF6, less than one month later on 21 April, was both a spectacular and highly symbolic moment in ITER history. A tokamak is essentially a vacuum chamber within a magnetic cage, and the 330-tonne ring-shaped PF6 was the first magnet to be positioned in the assembly pit.

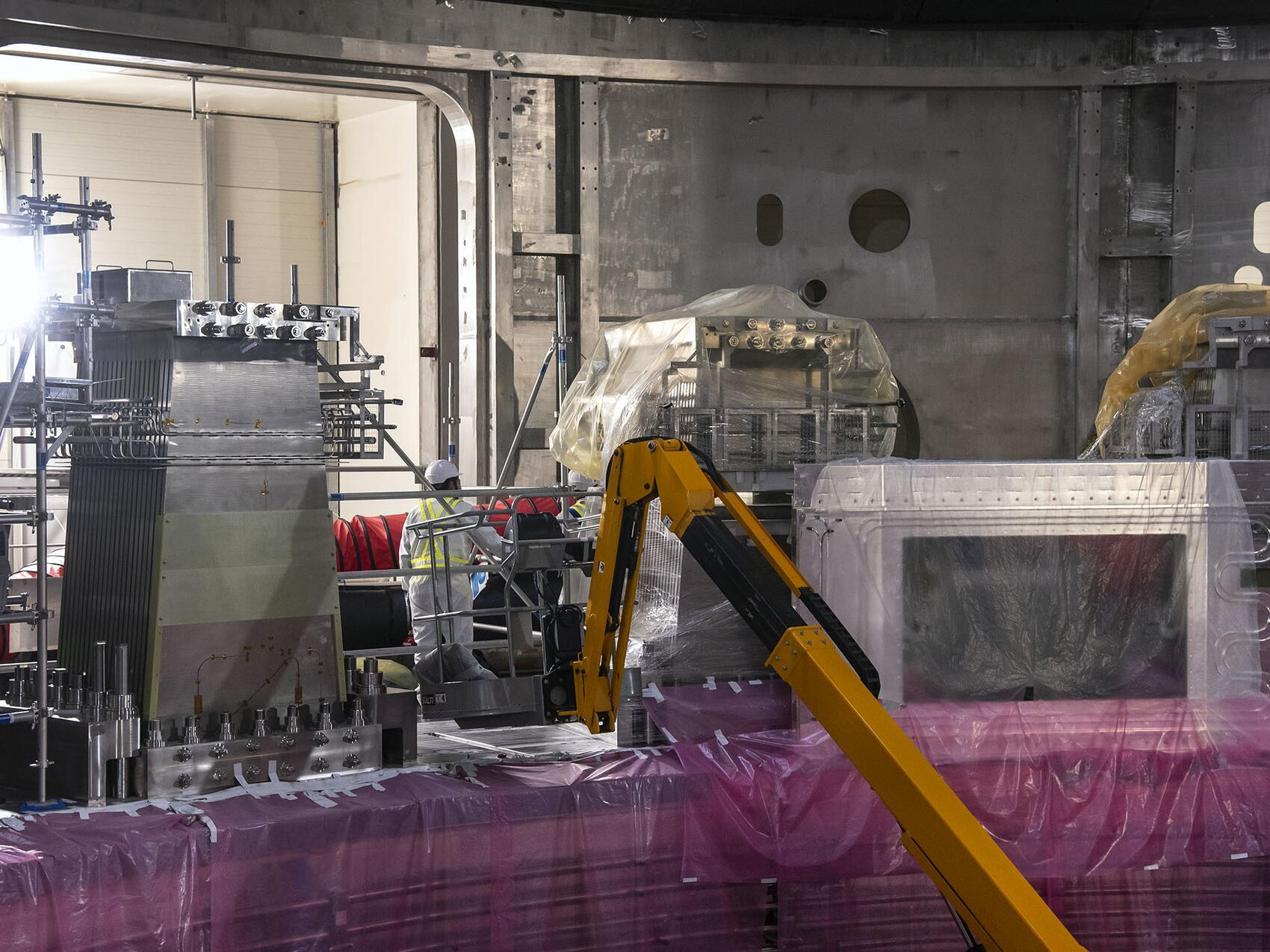

With little room to move and a lot of ongoing co-activity, workers are now busy installing support thermal shield panels to raise yet another thermal barrier, this time around the 18 toroidal field gravity supports.

In preparation for the installation of the next ring-shaped coil, poloidal field coil #5, workers are completing work on six temporary supports. Coil insertion in the pit is scheduled in late July/early August.

The amphitheatre is gone and the once majestic stage is now a cramped environment. But the ballet of workers, tools and machines, as pictured in the portfolio below, still makes for a splendid show.