ITER NEWSLINE

-

Ring coils

A fisheye view

Ring coils | A fisheye view

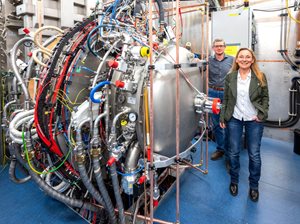

Three poloidal field coils are now present in Europe's on-site winding facility.

In this 257-metre-long production facility on the ITER site, European Domestic Agency contractors are producing four of ITER's six poloidal field magnets. A fifth, poloidal field coil #6, was manufactured under European contract in China and has arrived for cold testing.

To the far left of this fisheye image, poloidal field coil #5 (PF5), whose fabrication was launched in August 2017, has entered the final assembly phase and is being equipped with helium piping and electrical cables prior to cold test operations.

At the opposite end of the frame, half-hidden under the red gantry crane, the

recently delivered PF6 is being readied for a cold test campaign that is scheduled to begin in August. A cryogenic chamber for cold testing, partly open, is visible to the right. Cold testing consists in bringing down the coil's temperature to 80 K (minus 193 °C) in order to verify that the insulation is robust and that the component can be cooled to superconducting temperatures without incurring the formation of cracks.

The recently delivered PF6 is being readied for a cold test campaign that is scheduled to begin in August.

The same diameter (17 metres) as PF5 but considerably lighter (204 tonnes versus 342 tonnes), PF2 occupies the centre of the image. Workers are presently assembling a tight mould around the coil for the resin impregnation phase, set to begin in the coming weeks. Once impregnated, PF2 will be fitted with additional equipment (joints, clamps, etc.) and also cold tested.

In addition to the three fully formed poloidal field magnets visible in this image, work has begun far to the left on the preparatory activities for PF4 (24 metres in diameter, 350 tonnes). A dummy double pancake must be completed before actual fabrication is launched this summer.

Also see this report on the Fusion for Energy website.

return to the latest published articles