Identical in aspect and dimension to the diesel version (the red power pack closest to us), the electric power pack unit developed by Mammoet for ITER (the red power pack furthest from us) can sustain two days of standard operation on site before requiring a charge. In a world premiere on Friday 16 February, it powered the trailer that transferred toroidal field coil #12 from the Assembly Hall to a nearby storage facility.

For years, since ITER began handling massive components on site, transfer operations have depended on self-propelled modular trailers (SPMT) equipped with conventional diesel power pack units (PPU) pumping high-pressure oil into the trailer's hydraulic motors. Diesel motors are powerful and dependable but also noisy, and their exhaust—although filtered and evacuated when the SPMT is operating inside a building—is heavy with fumes and fine particles.

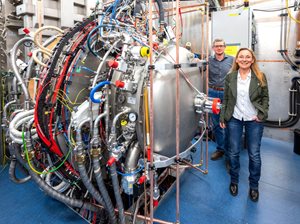

The batteries of the electric power pack (on the left) deliver 320 kW of power, equivalent to 460 hp, and can handle two days of standard operation on site before requiring a charge. (In order to avoid a complex reconfiguration, and also to have a backup, the diesel power pack unit on the right was kept attached to the trailer.)

Another advantage of the electric motor is silence. At 60 dB the noise generated is equivalent to that of a washing machine. "And electricity is much cheaper than diesel fuel," adds Bos who is now dealing with "dozens of requests" to produce more e.PPUs.