ITER NEWSLINE

-

Pressurized equipment

ITER can now act as inspector

Pressurized equipment | ITER can now act as inspector

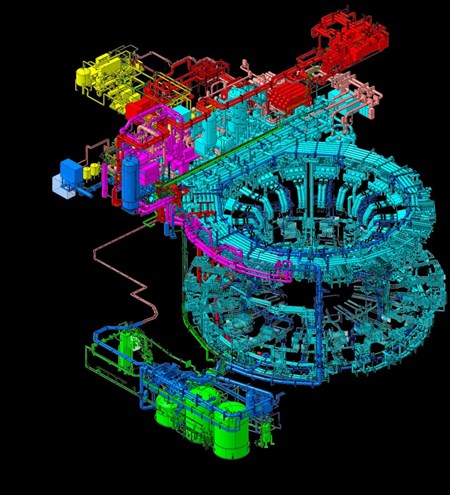

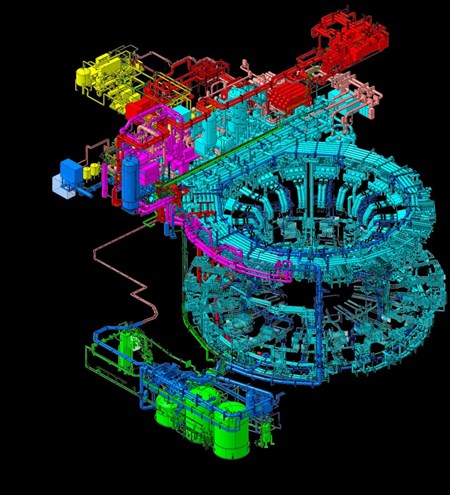

A component or system under pressure that contains (or might contain) activated elements falls under the category of "nuclear pressurized equipment." In ITER, components such as the vacuum vessel, the massive drain tanks that collect water from the cooling circuits in the case of leak or accidental situation, and the nearly 40-kilometre-long network of the Tokamak cooling water piping belong to this category.

The Tokamak cooling water system (TCWS) is one of the mechanical systems of the ITER machine that falls into the category of nuclear pressure equipment, which requires that conformity assessments be performed at every stage of fabrication. The ITER Organization has acquired ''Module H,'' which recognizes the Organization as a pressure equipment manufacturer with a full, certified quality assurance system.

French nuclear safety regulations, which ITER observes, require that conformity assessments be performed at every stage of the component or system's fabrication.

These assessments are performed by specialized companies called "Agreed Notified Bodies" that provide step-by-step validation of the design/manufacturing/installation processes and eventually deliver the certificate of conformity allowing the component or system to be commissioned.

Last week, following a lengthy and rigorous procedure, the ITER Organization successfully passed the audit to act as an Agreed Notified Body. "We now have internalized this capacity," says Joëlle Elbez-Uzan, head of the ITER Environmental Protection & Nuclear Safety Division. "We have acquired the so-called 'Module H', which validates the excellence of our integrated management system of regulatory requirements in the field pressure regulation."

Following this initial validation, Joëlle's Division will be audited every year by the certification agency Bureau Veritas.

For ITER, the internalization of a formerly contracted strategic function (and a costly one at that) translates into considerable savings.

return to the latest published articles