ITER NEWSLINE

95

Successful testing of first wall mock-ups

Russel Eaton, Senior Designer, ITER Blanket Section

Successful testing of first wall mock-ups

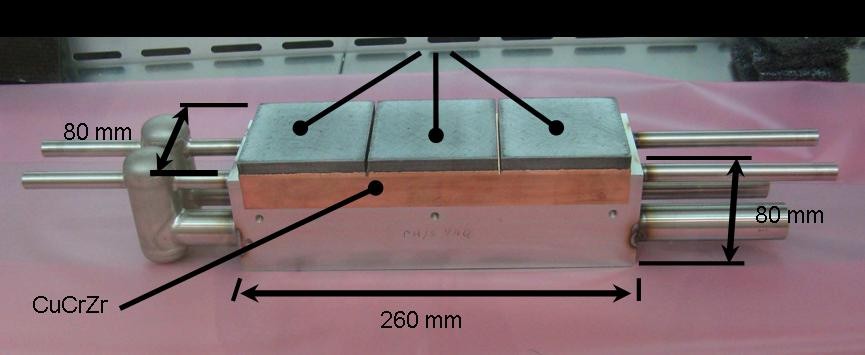

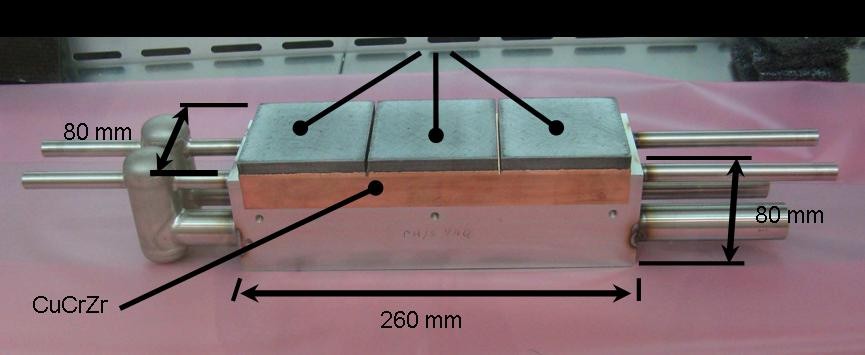

The European blanket first wall qualification mockup, with beryllium tiles.

The European Domestic Agency provided two identical first wall qualification mockups for the first test set. Each mockup was comprised of 3 x 80 mm x 80mm x 10 mm-thick beryllium armour tiles joined to a CuCrZr heat sink using hot isostatic pressing (HIP). A stainless steel beam structure and cooling pipes makes up the assembly.

One mockup was subsequently sent to both European and US test facilities for the thermal fatigue testing of the assemblies. In the US, tests were undertaken in the EB 1200 electron beam facility at Sandia National Laboratory, and in the EU, at the BESTH facility in Prague, Czech Republic and the JUDITH-II facility in Juelich, Germany.

Testing of the mockups comprised 12,000 "normal" cycles at heat flux levels of 0.88 MW/m² plus 1,000 "MARFE" (off-normal event) cycles at heat flux levels of 1.75 MW/m². Following the formal test campaign, the heat flux levels for both "MARFE" tests at both facilities was increased to a maximum 2.25 MW/m².

This maximum test level was defined not by the mockup, but by a facility-imposed maximum beryllium temperature. Tile temperatures above 600 °C lead to accelerated levels of beryllium deposition and facility clean-up can become a significant cost issue. In addition, mockups from other involved Domestic Agencies such as the US, China, Korea, Japan and the Russian Federation are currently undergoing testing in the European and American labs.

The first phase of first wall qualification is planned to be completed by December. This date is significant, as January 2010 sees the commencement of the second part of the qualification program: the large-scale semi-prototype program which will provide final qualification in readiness for signing the Procurement Arrangement in summer 2012.

return to Newsline #95