ITER NEWSLINE

113

Borated steel plate successfully fabricated

Borated steel plate successfully fabricated

The solid steel plate now waits for further testing trials in a Tore-Supra workshop. Craig Hamlyn-Harris opens the wrap for the photographer.

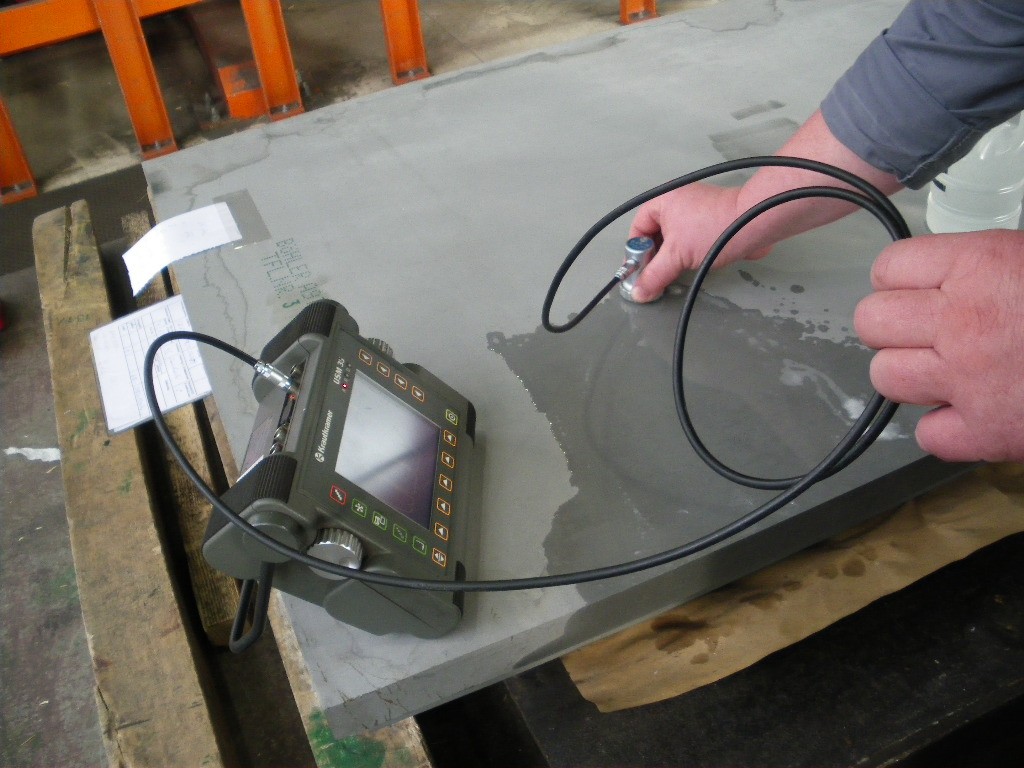

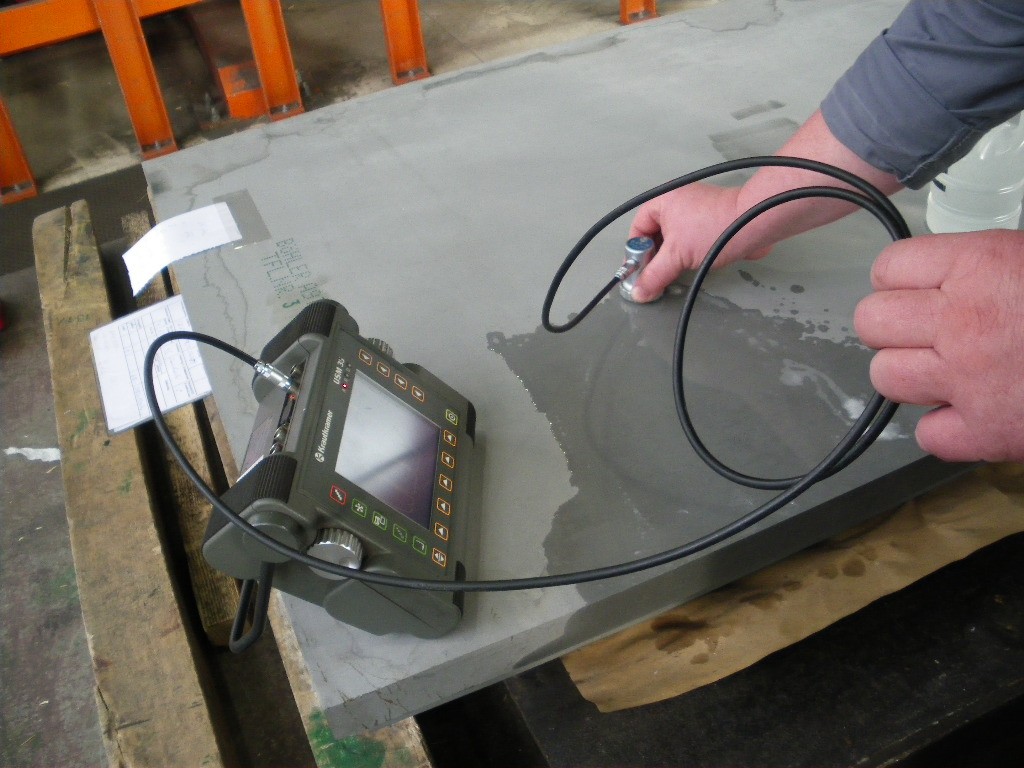

Ultra-sonic inspection for volumetric defect detection.

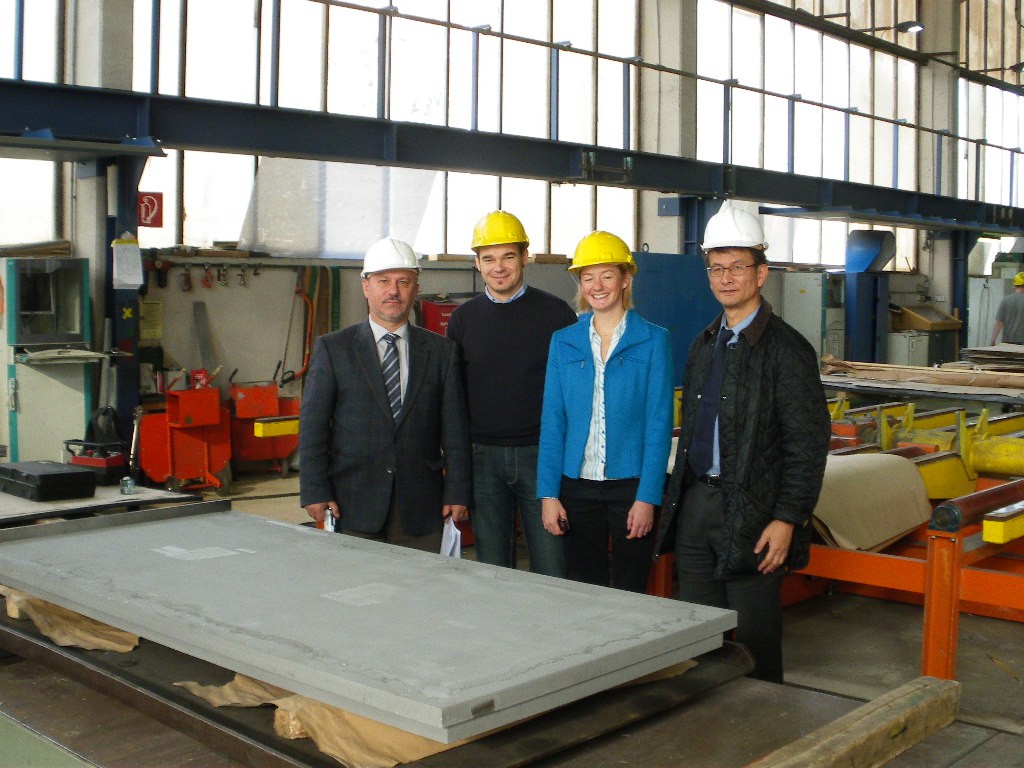

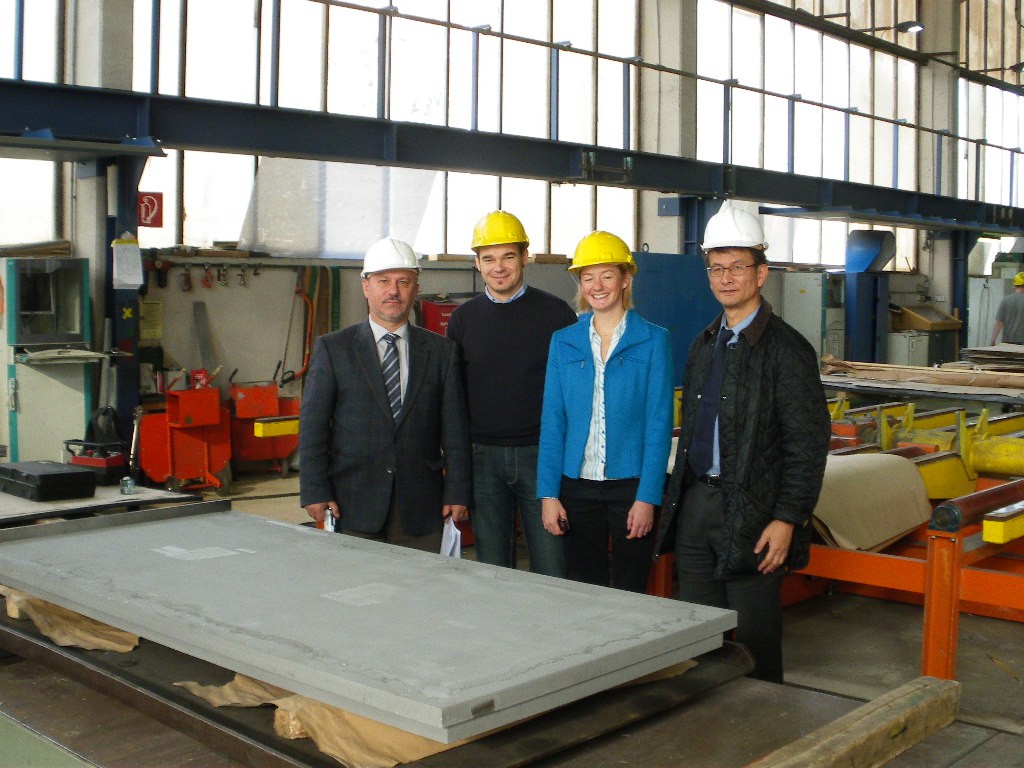

Vladimir Barabash (left) and Kimihiro Ioki (right) during their visit to the manufacturing site in Austria.

Boron has been widely used in the nuclear industry because of its neutron absorption capability. High neutron absorption capability combined with sufficient mechanical properties and corrosion resistance make borated steel an attractive material. If you manage to overcome its brittleness.

In recent tests performed under an ITER R&D contract, the Austrian company BÖHLER Bleche GmbH & Co KG, has now proved it possible. Several trials have been performed to optimize the technological process to avoid crack formation and to achieve the required mechanical properties and the surface quality. Two plates have been produced and are now waiting in a storage room in Cadarache for further tests.

return to Newsline #113