The Hyundai Heavy Industry shipyard, in Ulsan, South Korea, is one of the three largest in the world. Several hundred ships of all sizes and shapes are produced here annually.

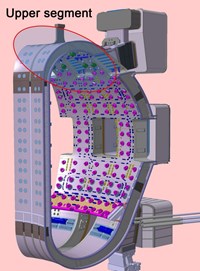

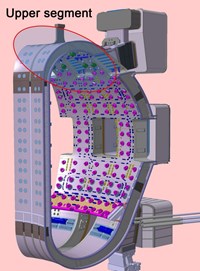

As impressive as the metallic piece before us is, it is only a small upper segment of one of the vacuum vessel sectors under Korean responsibility (see image). Once all the completed pieces are welded together, each sector will be 17 metres tall. These giant components will leave Korea by sea, before travelling to the inland ITER site in southern France by self-propelled transporter.

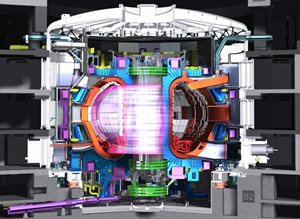

Home to the fusion reactions, the ITER vacuum vessel is made up of nine ''sectors.'' Europe will procure seven; South Korea, two.

Fabricating a "piece" of ITER requires submitting to a certain number of obligations for the supplier. But the benefits are clear: by participating in the fabrication of high-tech ITER components, companies have the opportunity to acquire a knowledge base and experience that is precious for its other areas of their activity as well as for future contracts in the domain of fusion.